Prefer to work with one of our design consultants? Complete this form to get help building your quote.

Prefer to work with one of our design consultants? Complete this form to get help building your quote.

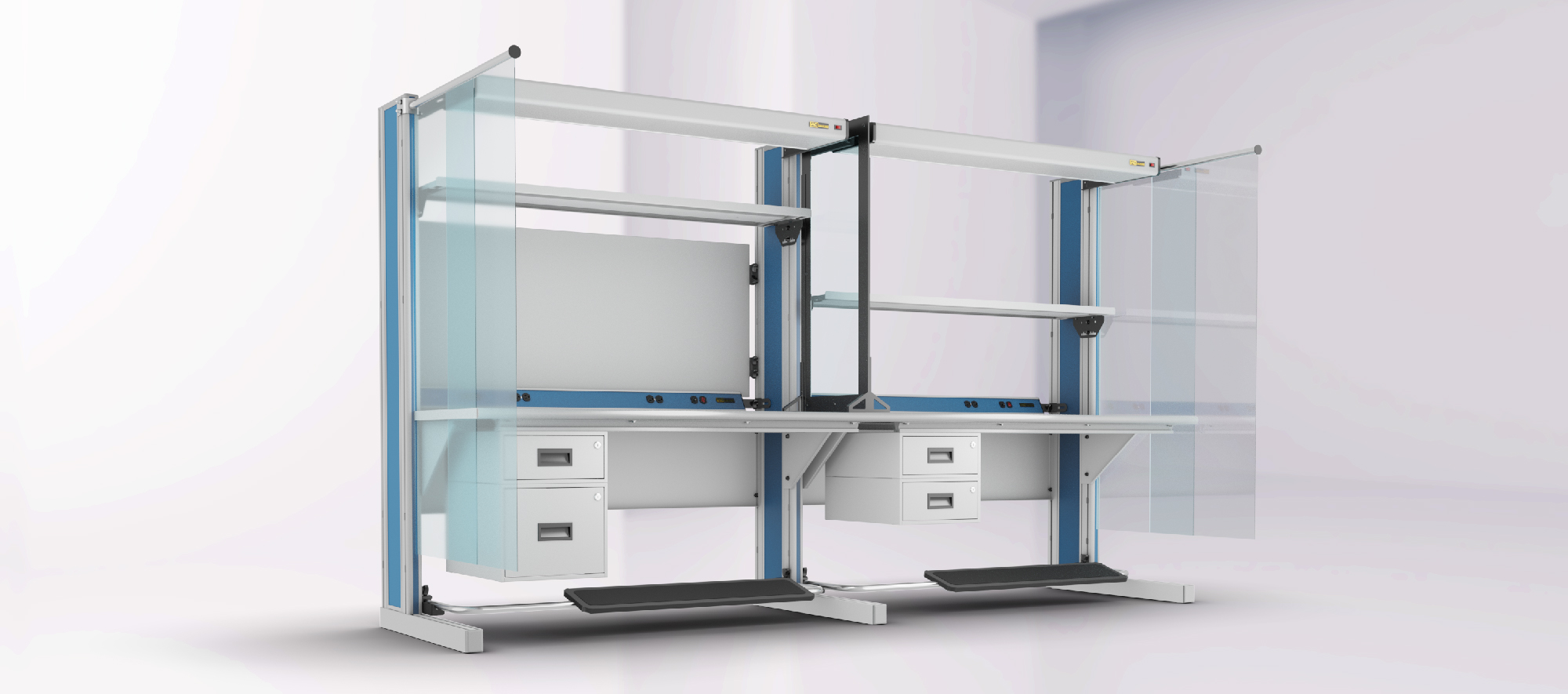

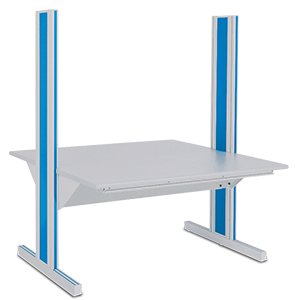

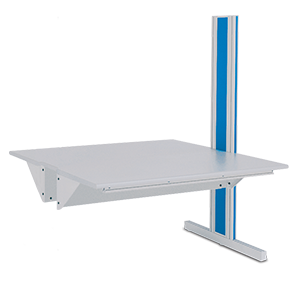

Dimension 4 Ergonomic Workstations are the most versatile and useful workstation modules available. The system easily expands to meet growing needs through the addition of accessories and more modules.

Our “Basic” units are available in Single-Sided or Double-Sided workstation configurations and are easily customized to meet a company's exact needs. And, with their intelligent design, Dimension 4 workstations can be quickly reconfigured any time your requirements change.

As with all IAC workstations, Dimension 4 Modular Workstation components are ergonomically designed to ensure maximum worker safety, improved efficiency and greater productivity.

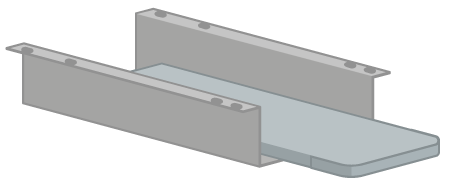

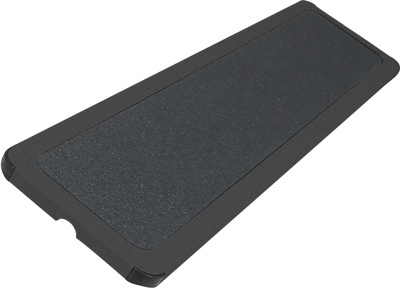

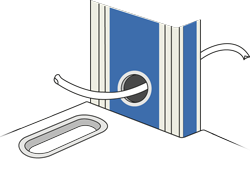

See how our worksurfaces are pre-inserted

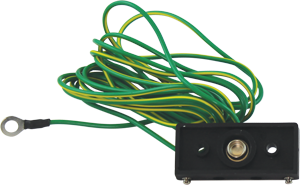

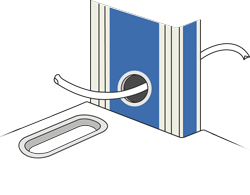

See how we pre-install ESD grounding bolts on ESD benches

IAC manufactures 100% of our products in our own facility where all processes meet or exceed industry specifications for quality. Our key design, manufacturing and customer service management represents more than 70 years combined experience in the workstation industry. And the majority of our production employees have been with the company for 15 years or more. All bring a craftsman's pride to the manufacture of IAC's workstations and workbenches.

IAC's manufacturing facility meets Class A specifications, with in-house operations for sheet metal fabrication using dedicated tooling, frame welding, laminating and finish, and a state-of-the-art powder paint bay. Continuous inspection and written procedures for every operation assure that high quality control standards are met at every stage of manufacturing. Whether selecting standard or customized models, IAC workstations offer the best value now and for years to come.

Standard Lengths: 48", 60", 72"

Standard Depths: 30", 36"

Upright Heights: 36", 48", 60", 72", 84"

Worksurface Height: Adjustable

Maximum Load

Single Sided: 750 lbs.

Double Sided: 1200 lbs.

IAC LLC' products are warranted to the original user to be free from defects in design, material and worksmanship, given normal use and care, for a period of ten (10) years of single shift service, from the date of purchase.

With the exceptions noted below, IAC LLC, at its option, will repair or replace any product or part thereof which fails as a result of such defect during the following warranty periods. (Pro-rated for multi-shift use.)

All IAC LLC' products (except as noted) ...Ten years Operating components, functional mechanisms, high-wear parts such as chair pneumatic cylinders and casters ...Five years Wood or wood/metal framed products..Two years Textiles, covering materials, foam, finishes, exposed wood, fabrics, laminated electrical components, and bench height adjustment cylinders...One Year.

Exclusion - HEPA filters (All HEPA filters are inspected, installed and tested at the factory and are certified to meet Federal Standar 209E)

This warranty is limited to the replacement and/or repair only, of such defective part(s) authorized in writing to be returned to IAC LLC with transportation charges and costs prepaid by the purchaser, and provided that examination by IAC LLC discloses such defect. In no way shall IAC LLC be responsible for any damage caused by the carrier, abuse, negligence, misuse, user modifications, or customer's material. IAC LLC does not warrant the matching of color, grain, or texture.

Accessories, component parts, and laminates not manufactured by IAC LLC are warranted only to the extent of the original manufacturer's warranty.

IAC LLC will not accept unauthorized charges for expenses (i.e. labor and freight) incurred by the customer. Products which have been repaired or altered by anyone other than IAC LLC; or without IAC LLC' written authorization; or in IAC LLC' judgement have been subject to misuse, neglect, or accident; or use outside specifications by purchases; or others are excluded from this warranty.

This warranty is in lieu of any other expressed or implied warranty, including any implied warranty of merchantability or fitness for a particular purpose, and of any other obligations or liability on the part of IAC LLC.

IAC LLC is committed to delivering the highest quality products that give our customers the greatest long-term value, including a lower total cost of ownership.

Total Cost of Ownership is a vital factor to consider whenever a captial investment is made. TCO takes into account more than just the purchase price. It also includes the "hidden costs" that are part of every purchase, including:

Industrial workbenches that deliver years of dependable service are less expensive in the long run then those that must be replaced regularly because they can't withstand operational rigors.

Trouble-free dependable workbenches pay for themselves faster than those that incur large or constant expenses associated with maintenance crews, replacement parts and lost work hours.

Industrial workbenches that offer a smooth upgrade path avoid becoming obsolete as requirements grow and/or change. This in turn provides a higher return on investment (ROI).

"One size fits all" is no longer acceptable in today's world where rising Workers' Compensation expenses and lost production hours can wreak havoc on anyone's bottom line.

The long-term value that high quality offers is evidenced in lower maintenance/replacement costs, higher worker morale and greater overall efficiency and productivity.

When all these factors are taken into account, it becomes easier to see how IAC differs from the competition.

IAC manufactures 100% of our products in our own facility where all processes meet or exceed industry specifications for quality. Our key design, manufacturing and customer service management represents more than 70 years combined experience in the workstation industry. And the majority of our production employees have been with the company for 15 years or more. All bring a craftsman's pride to the manufacture of IAC's workstations and workbenches.

IAC's manufacturing facility meets Class A specifications, with in-house operations for sheet metal fabrication using dedicated tooling, frame welding, laminating and finish, and a state-of-the-art powder paint bay. Continuous inspection and written procedures for every operation assure that high quality control standards are met at every stage of manufacturing. Whether selecting standard or customized models, IAC workstations offer the best value now and for years to come.

Below are your available color options for this product line. By choosing Send With Color Selection located in your shopping cart you will have the opportunity to choose color options before completing your quote request.

If you prefer to proceed without color options simply select Send Without Color Selection in your shopping cart and your quote will be sent immediately following the completion of the required information fields located in your shopping cart.

For projects requiring critical color match, please contact IAC for paint and/or laminate samples.

Note: Due to changes with the OEM (Original Equipment Manufacturer) manufacturing process of ESD laminate, slight color variations may occur in laminates manufactured in 2015 and after as compared to ESD laminate manufactured prior to 2015. Please consult your IAC Industries representative for review and questions.

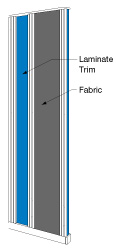

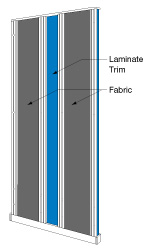

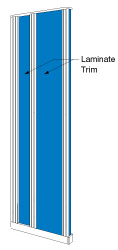

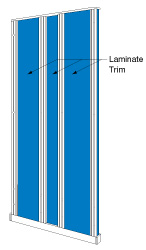

Trim and Accent color laminate must be specified when ordering Dimension 4 uprights, Pro Series, rolling carts, MAS and SAS, and Airclean Workstations.

Dimension 4 Ergonomic Workstations are the most versatile and useful workstation modules available. The system easily expands to meet growing needs through the addition of accessories and more modules.

Our “Basic” units are available in Single-Sided or Double-Sided workstation configurations and are easily customized to meet a company's exact needs. And, with their intelligent design, Dimension 4 workstations can be quickly reconfigured any time your requirements change.

As with all IAC workstations, Dimension 4 Modular Workstation components are ergonomically designed to ensure maximum worker safety, improved efficiency and greater productivity.

See how our worksurfaces are pre-inserted

See how we pre-install ESD grounding bolts on ESD benches

IAC manufactures 100% of our products in our own facility where all processes meet or exceed industry specifications for quality. Our key design, manufacturing and customer service management represents more than 70 years combined experience in the workstation industry. And the majority of our production employees have been with the company for 15 years or more. All bring a craftsman's pride to the manufacture of IAC's workstations and workbenches.

IAC's manufacturing facility meets Class A specifications, with in-house operations for sheet metal fabrication using dedicated tooling, frame welding, laminating and finish, and a state-of-the-art powder paint bay. Continuous inspection and written procedures for every operation assure that high quality control standards are met at every stage of manufacturing. Whether selecting standard or customized models, IAC workstations offer the best value now and for years to come.

Standard Lengths: 48", 60", 72"

Standard Depths: 30", 36"

Upright Heights: 36", 48", 60", 72", 84"

Worksurface Height: Adjustable

Maximum Load

Single Sided: 750 lbs.

Double Sided: 1200 lbs.

IAC LLC' products are warranted to the original user to be free from defects in design, material and worksmanship, given normal use and care, for a period of ten (10) years of single shift service, from the date of purchase.

With the exceptions noted below, IAC LLC, at its option, will repair or replace any product or part thereof which fails as a result of such defect during the following warranty periods. (Pro-rated for multi-shift use.)

All IAC LLC' products (except as noted) ...Ten years Operating components, functional mechanisms, high-wear parts such as chair pneumatic cylinders and casters ...Five years Wood or wood/metal framed products..Two years Textiles, covering materials, foam, finishes, exposed wood, fabrics, laminated electrical components, and bench height adjustment cylinders...One Year.

Exclusion - HEPA filters (All HEPA filters are inspected, installed and tested at the factory and are certified to meet Federal Standar 209E)

This warranty is limited to the replacement and/or repair only, of such defective part(s) authorized in writing to be returned to IAC LLC with transportation charges and costs prepaid by the purchaser, and provided that examination by IAC LLC discloses such defect. In no way shall IAC LLC be responsible for any damage caused by the carrier, abuse, negligence, misuse, user modifications, or customer's material. IAC LLC does not warrant the matching of color, grain, or texture.

Accessories, component parts, and laminates not manufactured by IAC LLC are warranted only to the extent of the original manufacturer's warranty.

IAC LLC will not accept unauthorized charges for expenses (i.e. labor and freight) incurred by the customer. Products which have been repaired or altered by anyone other than IAC LLC; or without IAC LLC' written authorization; or in IAC LLC' judgement have been subject to misuse, neglect, or accident; or use outside specifications by purchases; or others are excluded from this warranty.

This warranty is in lieu of any other expressed or implied warranty, including any implied warranty of merchantability or fitness for a particular purpose, and of any other obligations or liability on the part of IAC LLC.

IAC manufactures 100% of our products in our own facility where all processes meet or exceed industry specifications for quality. Our key design, manufacturing and customer service management represents more than 70 years combined experience in the workstation industry. And the majority of our production employees have been with the company for 15 years or more. All bring a craftsman's pride to the manufacture of IAC's workstations and workbenches.

IAC's manufacturing facility meets Class A specifications, with in-house operations for sheet metal fabrication using dedicated tooling, frame welding, laminating and finish, and a state-of-the-art powder paint bay. Continuous inspection and written procedures for every operation assure that high quality control standards are met at every stage of manufacturing. Whether selecting standard or customized models, IAC workstations offer the best value now and for years to come.

IAC LLC is committed to delivering the highest quality products that give our customers the greatest long-term value, including a lower total cost of ownership.

Total Cost of Ownership is a vital factor to consider whenever a captial investment is made. TCO takes into account more than just the purchase price. It also includes the "hidden costs" that are part of every purchase, including:

Industrial workbenches that deliver years of dependable service are less expensive in the long run then those that must be replaced regularly because they can't withstand operational rigors.

Trouble-free dependable workbenches pay for themselves faster than those that incur large or constant expenses associated with maintenance crews, replacement parts and lost work hours.

Industrial workbenches that offer a smooth upgrade path avoid becoming obsolete as requirements grow and/or change. This in turn provides a higher return on investment (ROI).

"One size fits all" is no longer acceptable in today's world where rising Workers' Compensation expenses and lost production hours can wreak havoc on anyone's bottom line.

The long-term value that high quality offers is evidenced in lower maintenance/replacement costs, higher worker morale and greater overall efficiency and productivity.

When all these factors are taken into account, it becomes easier to see how IAC differs from the competition.

Products offered in the Quick Ship program are shipped (based on quantities not to exceed ten units) on or before the fifth working day after receipt of order (ARO) – Normal lead times for Quick Ship are five (5) business days ARO, however all quick ship product requests are subject to availability and sometimes experience lead times between 5 – 10 business days. Quantities greater than ten (10) units are subject to review by factory before assigning ship dates and approval.

We are currently working on adding these Assembly Instructions to our website. In the meantime, please contact us at 1-800-229-1422 and we'd be happy to help you out.

See everything for this Series below. Add whichever components you'd like into your cart to receive your quote from IAC.

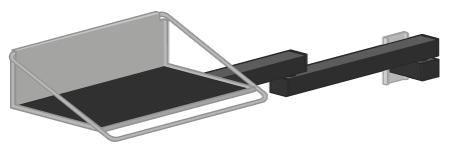

Single Sided Starter Units can be used in stand-alone applications or joined with adders to make in-line and cell systems.

The basic unit consists of two (2) uprights, worksurface, support brackets and hardware.

Dimension 4 workstations are shipped unassembled and the total weight capacity for a single sided starter is 750 lbs static load, evenly distributed.

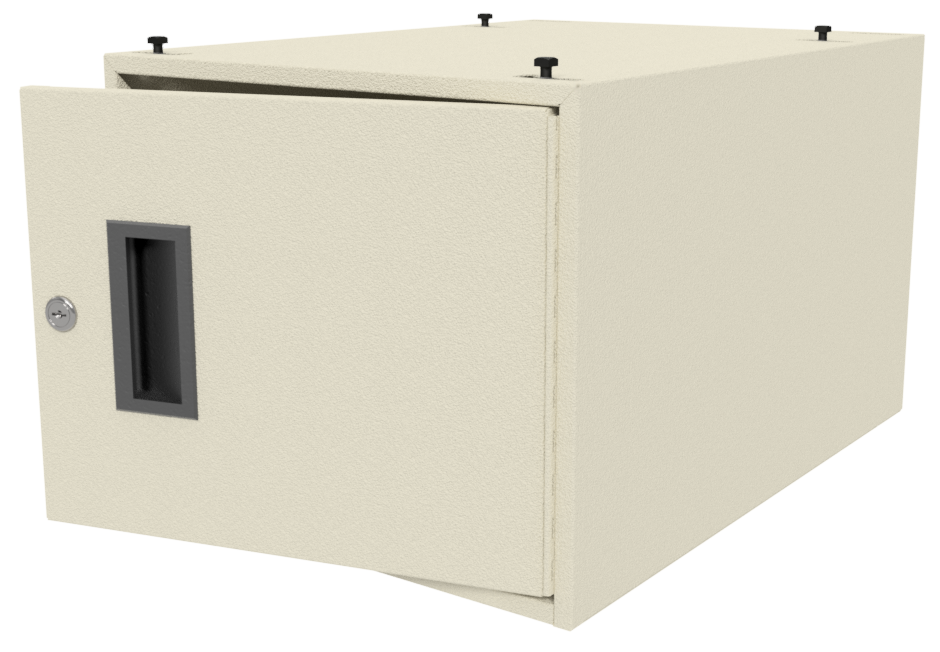

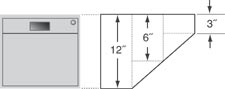

Single 3" drawer w/lock

Suspended Drawers & Cabinets:

Single 6" drawer w/lock

Suspended Drawers & Cabinets:

Double 6" Drawer w/lock

Suspended Drawers & Cabinets:

Single 12" file drawer w/lock

Suspended Drawers & Cabinets:

Single 12" locker w/lock - Left

Suspended Drawers & Cabinets:

Single 12" locker w/lock - Right

Suspended Drawers & Cabinets:

Triple drawer w/lock (3", 6", 12" sections)

Suspended Drawers & Cabinets:

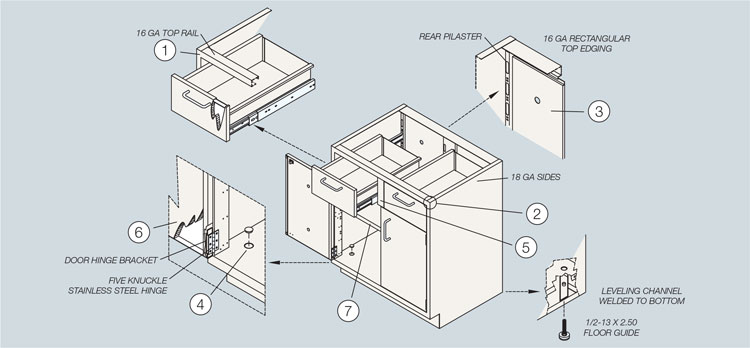

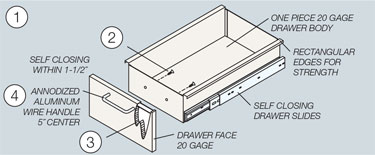

Standard Suspended Cabinets mount anywhere along the support channels below the worksurface.

Features

Eight 3" drawers

Suspended Drawers & Cabinets:

Individual Cylinder Lock

Gang-Locking Mechanism for Right Cabinets & All Drawers

Four 6" drawers

Suspended Drawers & Cabinets:

Gang-Locking Mechanism for Left Cabinets

Individual Cylinder Lock

Double 12" file drawer

Suspended Drawers & Cabinets:

Individual Cylinder Lock

Gang-Locking Mechanism for Right Cabinets & All Drawers

Double 6" drawer & 12" file drawer

Suspended Drawers & Cabinets:

Individual Cylinder Lock

Gang-Locking Mechanism for Right Cabinets & All Drawers

Double 3" drawer, three 6" drawers

Suspended Drawers & Cabinets:

Individual Cylinder Lock

Gang-Locking Mechanism for Right Cabinets & All Drawers

Four 3" drawers & 12" drawer

Suspended Drawers & Cabinets:

Individual Cylinder Lock

Gang-Locking Mechanism for Right Cabinets & All Drawers

Four 3" drawers, two 6" drawers

Suspended Drawers & Cabinets:

Individual Cylinder Lock

Gang-Locking Mechanism for Right Cabinets & All Drawers

Double 12" locker - Left

Suspended Drawers & Cabinets:

Gang-Locking Mechanism for Left Cabinets

Individual Cylinder Lock

Double 12" locker - Right

Suspended Drawers & Cabinets:

Gang-Locking Mechanism for Right Cabinets & All Drawers

Individual Cylinder Lock

Double 3" drawer & 18" locker w/shelf - Left

Suspended Drawers & Cabinets:

Extra Cabinet Shelf

Gang-Locking Mechanism for Left Cabinets

Individual Cylinder Lock

Double 3" drawer & 18" locker w/shelf - Right

Suspended Drawers & Cabinets:

Extra Cabinet Shelf

Gang-Locking Mechanism for Right Cabinets & All Drawers

Individual Cylinder Lock

Double 6" drawer & 12" locker - Left

Suspended Drawers & Cabinets:

Gang-Locking Mechanism for Left Cabinets

Individual Cylinder Lock

Double 6" drawer & 12" locker - Right

Suspended Drawers & Cabinets:

Gang-Locking Mechanism for Right Cabinets & All Drawers

Individual Cylinder Lock

Four 3" drawers & 12" locker - Left

Suspended Drawers & Cabinets:

Gang-Locking Mechanism for Left Cabinets

Individual Cylinder Lock

Four 3" drawers & 12" locker - Right

Suspended Drawers & Cabinets:

Gang-Locking Mechanism for Right Cabinets & All Drawers

Individual Cylinder Lock

Full 24" locker w/shelf - Left

Suspended Drawers & Cabinets:

Extra Cabinet Shelf

Individual Cylinder Lock

Full 24" locker w/shelf - Right

Suspended Drawers & Cabinets:

Extra Cabinet Shelf

Individual Cylinder Lock

Single 6" drawer & 18" locker w/shelf - Left

Suspended Drawers & Cabinets:

Extra Cabinet Shelf

Gang-Locking Mechanism for Left Cabinets

Individual Cylinder Lock

Single 6" drawer & 18" locker w/shelf - Right

Suspended Drawers & Cabinets:

Extra Cabinet Shelf

Gang-Locking Mechanism for Right Cabinets & All Drawers

Individual Cylinder Lock

Standard Suspended Cabinets mount anywhere along the support channels below the worksurface.

Features

Gang-Locking Mechanism for Left Cabinets

Gang-Locking Mechanism for Right Cabinets & All Drawers

Individual Cylinder Lock

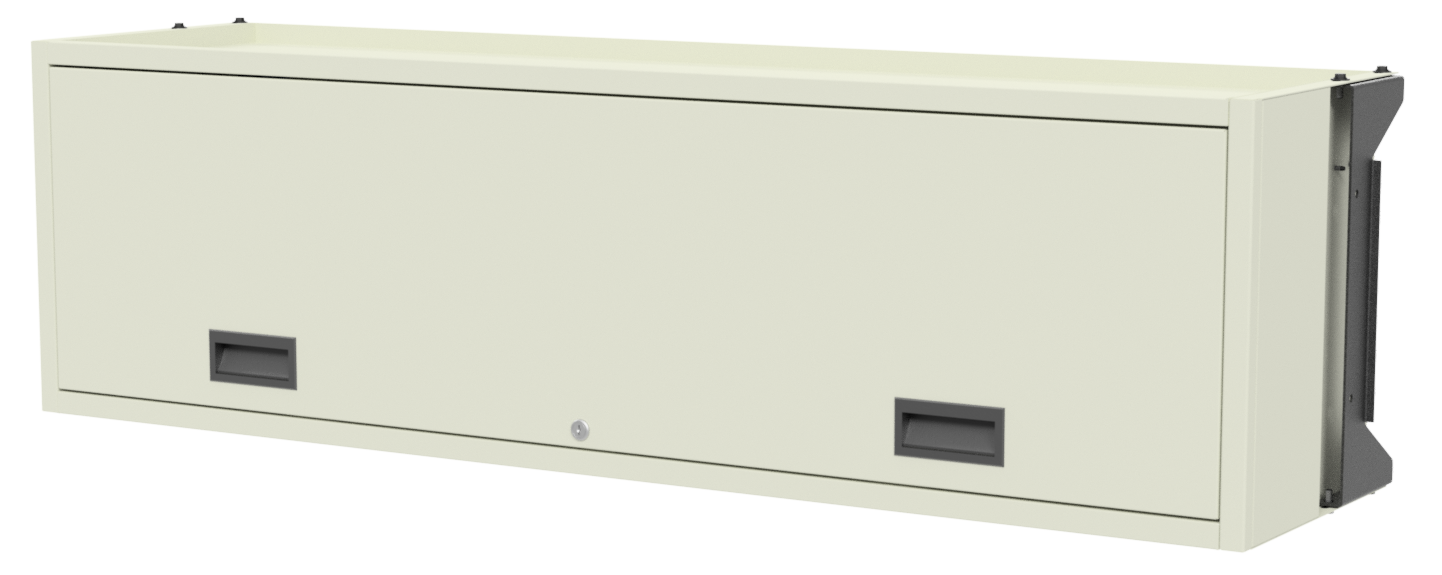

Double Flipper Door Overhead Storage Cabinet

If workstation is Basic or has a Standard Electrical System (SES) upgrade, choose "Not PDS" in Electrical System D4 menu. If workstation has a Power Distribution System (PDS-II) upgrade, choose "Is PDS".

Single Flipper Door Overhead Storage Cabinet

If workstation is basic or has an Standard Electrical System (SES) upgrade, choose "Not PDS". in Electrical System Choice below. If workstation has a Power Distribution System (PDS-II) upgrade, choose "Is PDS".

Sliding Door Overhead Storage Cabinet

If workstation is basic or has an Standard Electrical System (SES) upgrade, choose "Not PDS". in Electrical System Choice below. If workstation has a Power Distribution System (PDS-II) upgrade, choose "Is PDS".

Laminated Shelf - Standard Duty — 75 lb. Maximum Capacity

Laminated Shelf - Heavy Duty — 150 lb. Maximum Capacity

Metal Shelf - Standard Duty — 75 lb. Maximum Capacity

Metal Shelf - Heavy Duty — 150 lb. Maximum Capacity

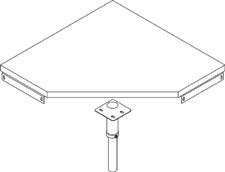

Radius Back – Corner Shelves

Corner Shelf Assemblies:

Square Back – Corner Shelves

Corner Shelf Assemblies:

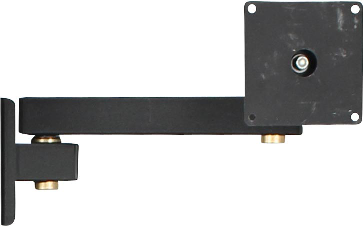

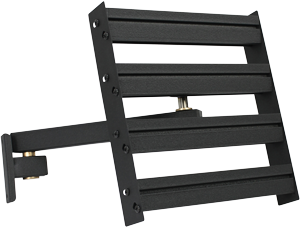

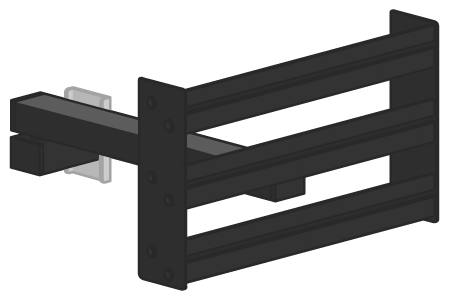

Premium Flat Panel Monitor Arms

(Keyboard Holder sold separately)

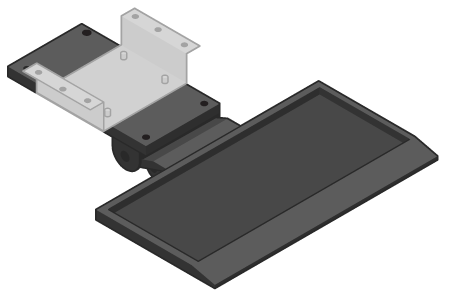

Flat Panel Display Keyboard Holder with Mouse Pad

Flat Panel Display Arm

(Keyboard Holder sold separately)

Flat Panel Display Keyboard Holder with Mouse Pad

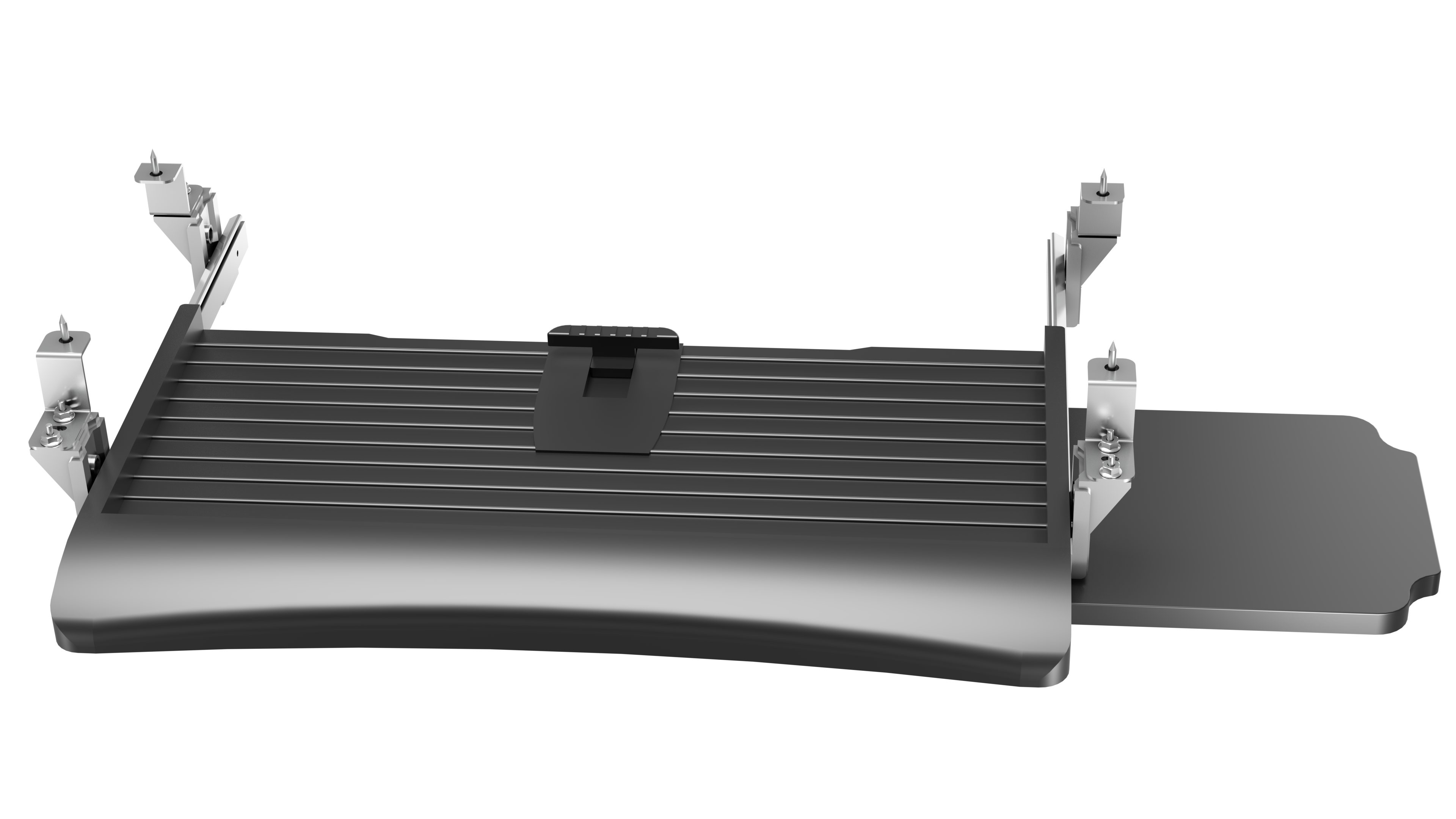

Articulating Keyboard Holder

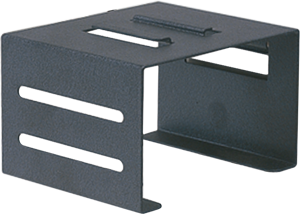

Slide-Out Universal CPU Holder

Adjustable Keyboard Holder

CRT Swing Arm Platform

25 lb. Capacity

75 lb. Capacity

Standard Keyboard Holder

75 lbs. CRT Stationary Platform

Side Mount Keyboard Holder

Frame Mounted Ergo Footrest Tube

Standard Footrest Tube

Industrial Footrest

IAC freestanding footrests are always a better choice for cabinet configurations, or when frame mounting is not an option due to structural interference or workstation design. Their portability allows them to be easily moved out of the way for cleaning. Also, freestanding footrests are more easily configured for a variety of workers, since their height and distance from the user can be adjusted without the use of a tool.

Specifications

Mini Industrial Footrest

IAC freestanding footrests are always a better choice for cabinet configurations, or when frame mounting is not an option due to structural interference or workstation design. Their portability allows them to be easily moved out of the way for cleaning. Also, freestanding footrests are more easily configured for a variety of workers, since their height and distance from the user can be adjusted without the use of a tool.

Specifications

Ergo Footrest Pan

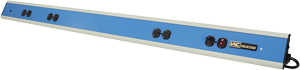

Electrical Channel

Extra PDS-II Duplex Receptacles & Bezel Trim

Grounding Block

PDS-II Power-Up Cables

PDS-II Simplex Receptacles

PDS-II Station Interconnects

Station Interconnects pass four 20 amp power circuits from one PDS-II upright to the next.

Personal Grounding Kit

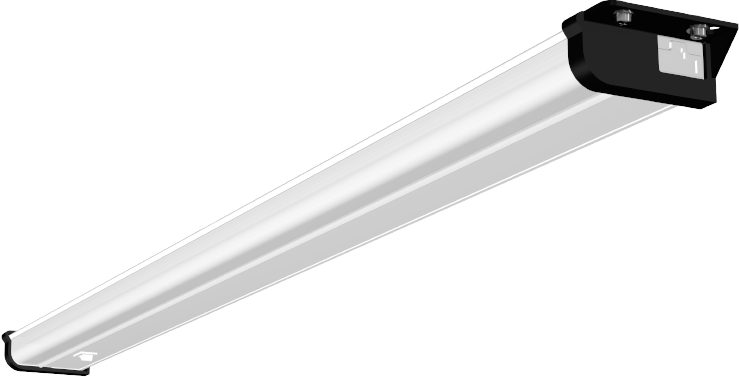

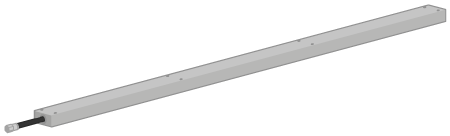

Under Shelf Lighting

Good lighting is essential for productive work areas. These LED under counter lights mount beneath the Instrument Shelf to keep the worksurface below well illuminated. All units are supplied with LED strip installed, an 5 ft. power cord (may also be hardwired) and switch.

Mag Light Holder

Light Fixture with Prismatic Diffuser

Offers the widest angle of light diffusion. Prismatic Diffusers are flat sheets of plastic with a prismatic configuration on the bottom surface to direct light rays at the highest angles from the fixture plane.

| Light Output | Details |

|---|---|

| Standard | Prismatic diffuser |

| High | Output approximately 20% more light than Standard fixture. Excellent for low ambient light environments. |

| 3-Tube | Allows control of all three tubes, so that one, two or three tubes can be turned on or off. |

Light Fixture with Direct Overhead Light (DOL) Diffuser

These white plastic diffusers feature a modern “open lattice” or “egg crate” design. Aesthetically pleasing and comparable in light to the Prismatic Diffuser.

| Light Output | Details |

|---|---|

| Standard | Prismatic diffuser |

| High | Output approximately 20% more light than Standard fixture. Excellent for low ambient light environments. |

| 3-Tube | Allows control of all three tubes, so that one, two or three tubes can be turned on or off. |

Light Fixture with Parabolic Diffuser (PD)

Parabolic Diffusers direct light rays directly down from the light fixture (25º cutoff). They are beneficial for reducing direct glare, especially for workers at standing workstations and for those at surrounding workstations. Note: Parabolic Diffusers deliver slightly less light to the worksurface compared to other IAC diffusers.

| Light Output | Details |

|---|---|

| Standard | Prismatic diffuser |

| High | Output approximately 20% more light than Standard fixture. Excellent for low ambient light environments. |

| 3-Tube | Allows control of all three tubes, so that one, two or three tubes can be turned on or off. |

IAC designs and manufactures its own lighting fixtures.*

Features

The Dimension 4 light fixture mounts to the upright and adjusts up/down and backwards/forwards. The fixture also tilts on its axis to better direct the light on the work and away from the operator’s eyes to reduce fatigue-inducing glare.

* Except Under Shelf Lighting.

LED Light Fixture with Prismatic Diffuser

LED Light Fixture with Direct Overhead Light (DOL) Diffuser

LED Light Fixture with Parabolic Diffuser (PD)

LED Light Fixture Retrofit Kit

IAC manufacturers these premium lighting fixtures with triple axes adjustability. Also select from a choice of light diffusers to obtain the optimum light for any task.

Two Light Models (Green, Red)

Solder Station Platform Swing Arm

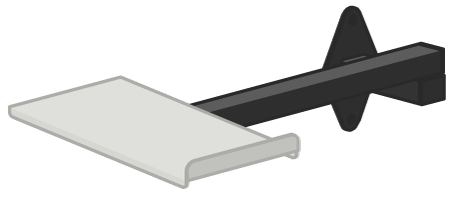

Swing Arm Document Holders

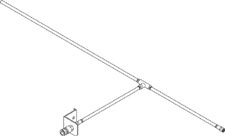

Swing Arm Extension Arm

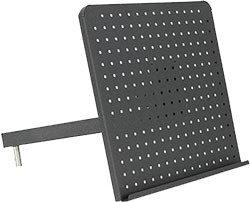

Swing Arm Pegboard

Swing Arm Tool Caddy

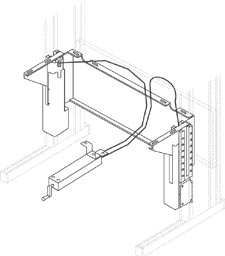

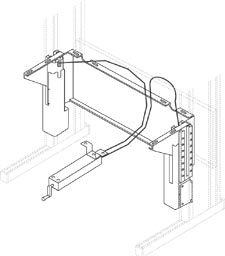

Standard Trolley – 25 Lbs., Max.

Extra Slide Tool Hanger – Standard

Heavy Duty Trolley – 35 Lbs., Max.

Extra Slide Tool Hanger – Heavy Duty

Tool Trolley Air System

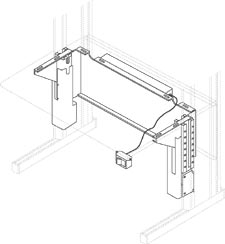

The Tool Trolley allows the operator to access air or electric tools from above. Ergonomically designed to aid the operator with the repetitive reaching of tools. The Tool Trolley mounts to the D4 uprights and includes one slide tool hanger. Additional sliding tool hangers are available as an option.

Tool Trolley provides free travel across entire width of worksurface. Use pneumatic or electrical tools.

Parts Cup Rail

Ergo Parts Cup Rail

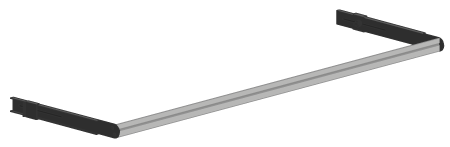

Standard Parts Cup Rails extend the full width of the workstation, and accept standard parts cup(s) and other accessories. Ergo Parts Cup Rails adjust up/down and back/forth to aid the operator with repetitive reaching motion, are of heavy duty construction, and additionally allow the angle of the parts cup to be adjusted.

12 Bin Parts Cup Rack Swing Arm

9 Bin Parts Cup Rack Swing Arm

Solder Spool Rail

Bottle Holder

Organization is a key to productivity. Keep important tools and components close at hand and off the worksurface. Attach to bin rails, side rack, tabletop tiered bin rack or shelf lip.

Double Solder Spool Holder

Kimwipe® Box Holder

Organization is a key to productivity. Keep important tools and components close at hand and off the worksurface. Attach to bin rails, side rack, tabletop tiered bin rack or shelf lip.

Solder Spool Holder

Organization is a key to productivity. Keep important tools and components close at hand and off the worksurface. Attach to bin rails, side rack, tabletop tiered bin rack or shelf lip.

Tool Holder

Organization is a key to productivity. Keep important tools and components close at hand and off the worksurface. Attach to bin rails, side rack, tabletop tiered bin rack or shelf lip.

Modular Vertical Flow Workstation

For Single Sided Dimension 4 Systems

Double Sided Systems

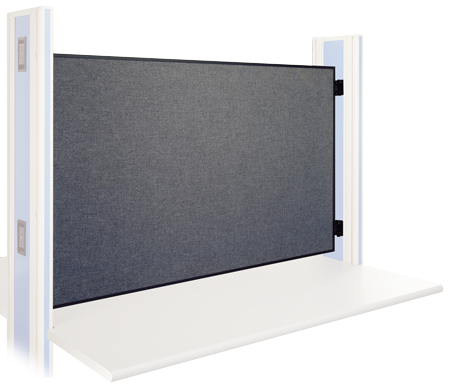

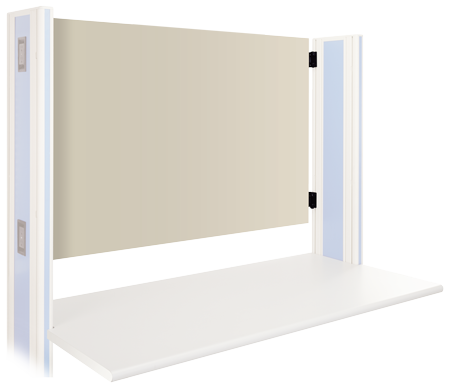

Single Sided Panel Mount

Double Sided (no cab) – Fabric

Double Sided (no cab) with SES or PDS – Fabric

Double Sided With Flipper Door Cab – Fabric

Double Sided with SES or PDS – Fabric

Single Sided – Metal

Double Sided (no cab) – Metal

Double Sided (no cab) with SES or PDS – Metal

Double Sided With Flipper Door Cab – Metal

Double Sided with SES or PDS – Metal

Standard – Single Sided End Panel – Fabric

SES – Single Sided End Panel – Fabric

PDS-II – Single Sided End Panel – Fabric

SES – Double Sided End Panel – Fabric

PDS-II – Double Sided End Panel – Fabric

Standard – Double Sided End Panel – Fabric

Standard – Single Sided Upright

SES – Single Sided Upright

PDS-II – Single Sided Upright

Standard – Double Sided Upright

SES – Double Sided Upright

PDS-II – Double Sided Upright

Standard – Single Sided End Panel – Laminate

SES – Single Sided End Panel – Laminate

PDS-II – Single Sided End Panel – Laminate

Standard – Double Sided End Panel – Laminate

SES – Double Sided End Panel – Laminate

PDS-II – Double Sided End Panel – Laminate

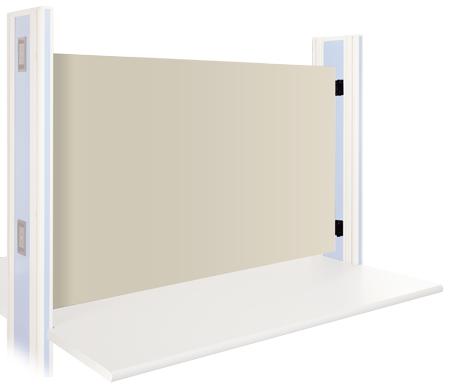

Modesty Panel

Hat Section

Top Support Brackets

Optional Heavy Duty Frame Upgrade

Slide Rail System

Single Slide Rail Option

Drop Cloth Option

Bin Holder Option

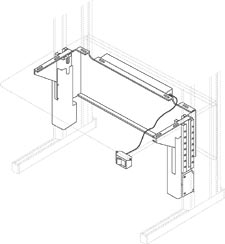

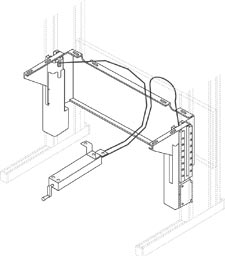

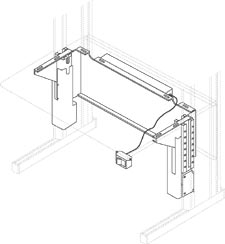

Manually operated, our hand crank models raise or lower the worksurface approximately one inch per five crank revolutions. They operate hydraulically and are designed to retrofit to existing Dimension 4 workstations with little alteration to existing parts. Each Single or Double Side Kit is supplied with all components required for transforming a standard D4 workstation into a hand crank hydraulic adjustable height workstation (each unit adjusts a single worksurface – two units are required to control both worksurfaces on Double Side workstations). Please review the the Ordering Tips for this product.

For Single Side Workstations – Manual

For Double Side Workstations – Manual

For Single Side, Multi-Unit Systems – Manual

For Double Side, Multi-Unit Systems – Manual

These motorized hydraulic adjustable height units are designed to retrofit to existing Single- or Double-Side Dimension 4 workstations with little alteration to existing parts. They are supplied with all components required for transforming a standard D4 workstation into a motorized hydraulic adjustable height workstation (each unit adjusts a single worksurface – two units are required to control both worksurfaces on Double Side workstations). Please review the the Ordering Tips for this product.

For Single Side Workstations – Motorized

For Double Side Workstations – Motorized

For Single Side, Multi-Unit Systems – Motorized

For Double Side, Multi-Unit Systems – Motorized

Oval Grommet – 2-1/2" x 6"

Round Grommets – 2-1/2" Diameter

End Panel on Left Side

End Panel on Right Side

End Panel on Both Sides

Manually operated, these models raise or lower the worksurface approximately one inch per five crank revolutions. The hand crank adjustable height upgrade must be purchased at the same time as the workstation and is available for both Single and Double Side workstations (each unit adjusts a single worksurface – two units are required to control both worksurfaces on Double Side workstations). Please review the Ordering Tips for this product.

Single Side Workstations Handcrank Upgrade

Double Side Workstations Handcrank Upgrade

On Double Side mechanisms, a support panel is added between and at the bottom of the uprights as a workstation stabilizer and to assist with the assembly of the units. Please review the the Ordering Tips for this product.

Single Side Workstations Motorized Upgrade

Double Side Workstations Motorized Upgrade

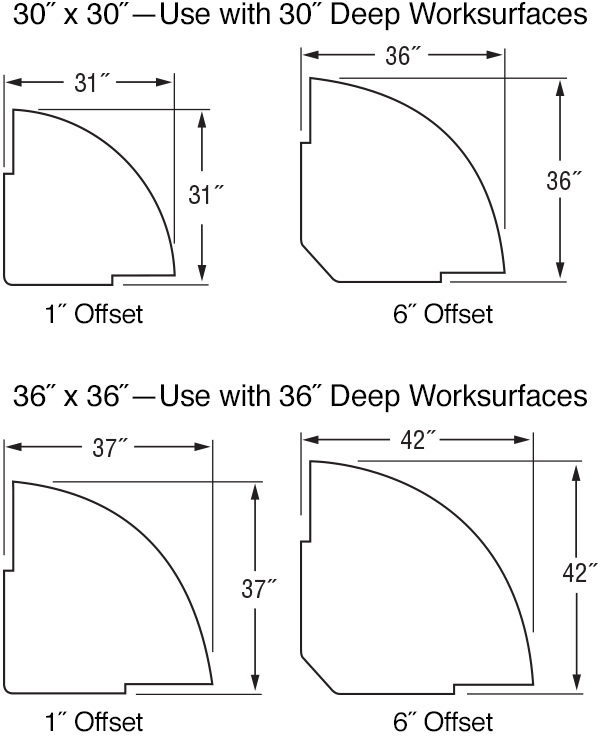

Radius Back – Worksurface Assembly

Square back corner worksurfaces include a rear support leg.

©2025, IAC, a Division of Treston. All rights reserved. Call: (714) 990-8997 Fax: (714) 990-0557 or E-mail: labsales@iacindustries.com

For immediate help with building your quote.

Outside business hours? Email us and we'll get back to you ASAP.

And we'll get back to you right away for more info so we can build your quote.

For immediate help with your quote call us at

Mon-Fri 7am - 4:30pm PST

Check your inbox for an email from us with a few questions to get your quote started.

For immediate help with your quote call us at

Mon-Fri 7am - 4:30pm PST